SONUS EVO Lite

EVO’s powerful technology for even deeper integration

< 150 g.

1.5 W POWER CONSUMPTION

EVO’S TRUSTED ARCHITECTURE

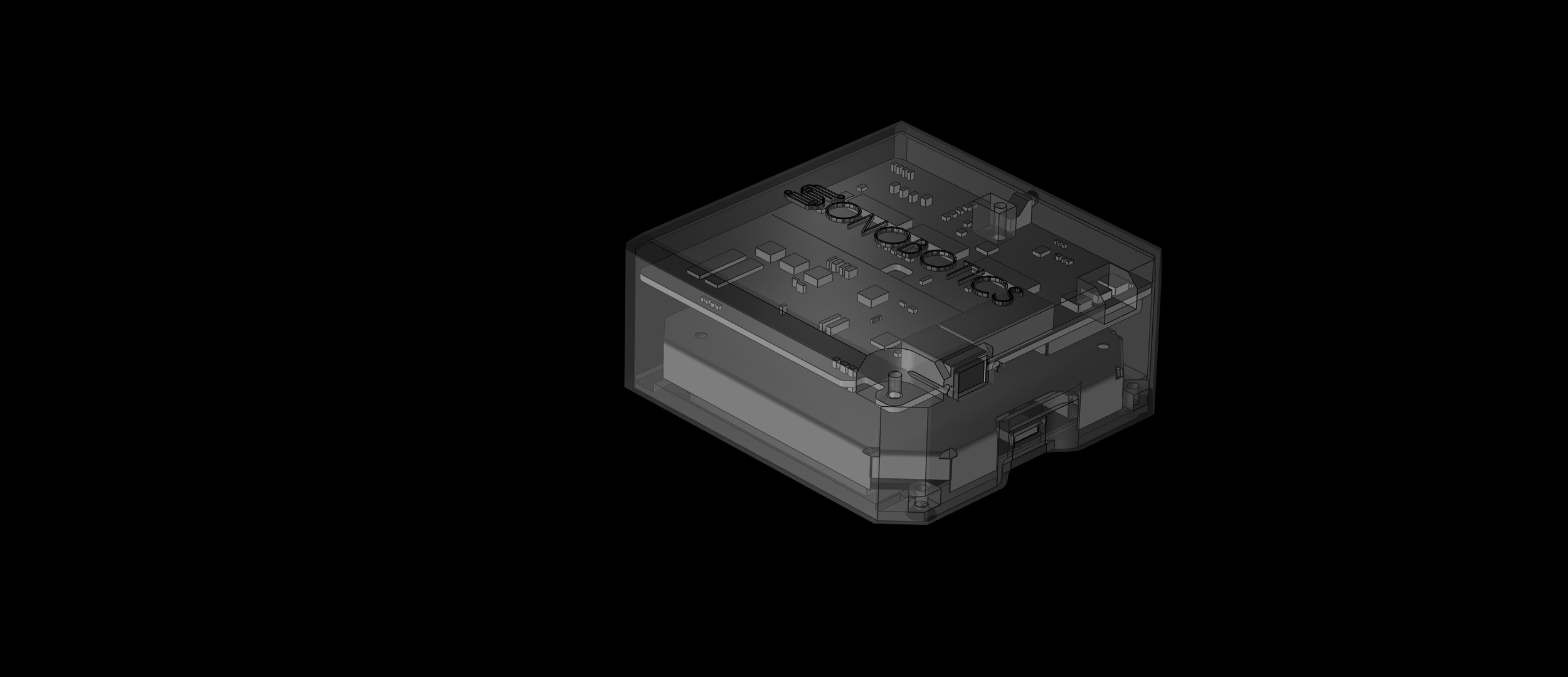

SONUS EVO Lite is the world’s lightest EMAT acquisition system which enables, for the first time, even deeper hardware and software integration capabilities by utilising the existing onboard processor of the robot.

Based on SONUS EVO’s trusted core technology, the EVO Lite offers non-contact ultrasonic testing (UT) without the need for couplant or surface preparation. Extremely compact, modular and compatible with the Robotic Operating System (ROS), SONUS EVO Lite allows seamless integration on to all types of robots within minutes.

Opening new possibilities to advance NDT inspection for robotics.

INCREDIBLY SMALL. UNBELIEVABLY POWERFUL.

Comparison to SONUS EVO:

40% LIGHTER WEIGHT

>75% MORE ENERGY EFFCIENT

EVO’S TRUSTED CORE TECHNOLOGY

UNCOMPROMISED MEASUREMENT ROBUSTNESS

“LIGHTER THAN YOUR PHONE”

EXTREMELY-COMPACT size

ULTRA-LIGHTWEIGHT: 150 g

EVEN LOWER POWER: < 1.5 W power use

SEAMLESS INTEGRATION INTO ROBOTS

DEEP HARDWARE AND SOFTWARE INTEGRATION with robot’s onboard processor

ROBOTIC OPERATING SYSTEM (ROS) software capability

USB 3 COMMUNICATION with the robot

EMBEDDED SIGNAL PROCESSING which outputs full A-Scans and material thickness values

INSPECTION CAPABILITIES

Thickness Mapping

SONUS EVO Lite, alongside our dedicated EMAT probes, is engineered to continuously acquire material thickness data at up to 12 Hz without the need for surface preparation or couplant. Such technology is designed to generate detailed material thickness maps ideal for corrosion and structural health monitoring (SHM) applications.

Crack Detection

With two fully-independent EMAT acquisition channels, along with our novel EMAT design, SONUS EVO Lite* is capable of performing simultaneous thickness and defect monitoring. This unique capability, not only enables defect sizing and orientation estimation, but can also be used to measure other material properties such as anisotropy.

*2-channel version

For more information and orders

TECHNICAL SPECIFICATIONS

Ultrasonic Channels

1 (2 optional)

Bandwidth

2 - 5 MHz

Measurement Modes

Pulse-Echo

Inspection Types

Thickness Measurement, Crack Detection (2-Channel Version)

System Output

Full A-Scan, Material Thickness Value

Thickness Monitoring / Crack Detection (2-Channel Version)

2 mm – +100 mm Thickness Range

0.05mm* Thickness Repeatability

3 Hz – 12 Hz Ultrasonic Data Acquisition Rate

Simultaneous Thickness and Crack Monitoring (with 2-Channel Version)

2.5 mm Max. Tolerable Probe Lift-Off

In-situ / High Temperature Inspection ( +30 mins @ 80°C, +15 mins @ 120°C )

Minimal Surface Preparation

RF Pulser

Toneburst Waveforms 2 – 5 Cycles

A/D Converter

14-bit, 100 MHz

Evaluation Gates

Automatic Peak Detection, User Adjustable

Communication

USB 3 and above

ROS Version

ROS 1

Probe Connector

LEMO 2 Pin 0B

Max. Power Consumption

1.5 W

Dimensions

88 L x 86 W x 38 H (mm)

Weight

< 150 g (0.33 lbs)

* Representative performance benchmark obtained on a mild steel plate with a 10 mm nominal thickness using 10 averages.